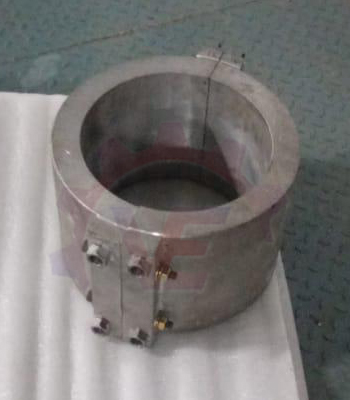

Jacket & Casting Heaters

Aluminum Cast Heaters represent a high-quality and efficient heating solution for various applications, including Extruders, Compression Molding Platens, Heat Sealers, and Vacuum Forming Platens.

These heaters offer exceptional temperature control accuracy, with the ability to maintain temperatures within +/-2 degrees, thanks to their heat-cool capabilities.

Key Features:

- Available in a range of sizes and watt densities, spanning from 10 to 60 watts per square inch.

- Pressure casting ensures a dense, porosity-free casting that can be equipped with either cooling fins or seamless stainless steel cooling tubes.

- Aluminum Cast Heaters can be cast into virtually any shape and size, allowing for complete coverage of the part to be heated and seamless integration with the equipment. Most Cast-in heat-cool bands are customized to meet specific customer requirements.

- These heaters are resistant to contamination and corrosion, making them highly durable and capable of withstanding high temperatures and pressures in demanding environments, providing years of trouble-free service.

Advantages:

- Capable of operating at high temperatures.

- Can be equipped with liquid cooling or air-cooling fins.

- Available in any size or shape, catering to diverse heating needs.

- Pressure casting ensures a porosity-free, high-density casting.

- Exceptionally robust and resistant to damage.

- Precise and accurate temperature control is achievable due to the heat-cool action.

- High watt densities are available, making them suitable for a wide range of applications.

Aluminum Cast Heaters offer a reliable and versatile solution for applications that demand efficient and precise heating with the ability to maintain tight temperature control, even in challenging operating conditions.